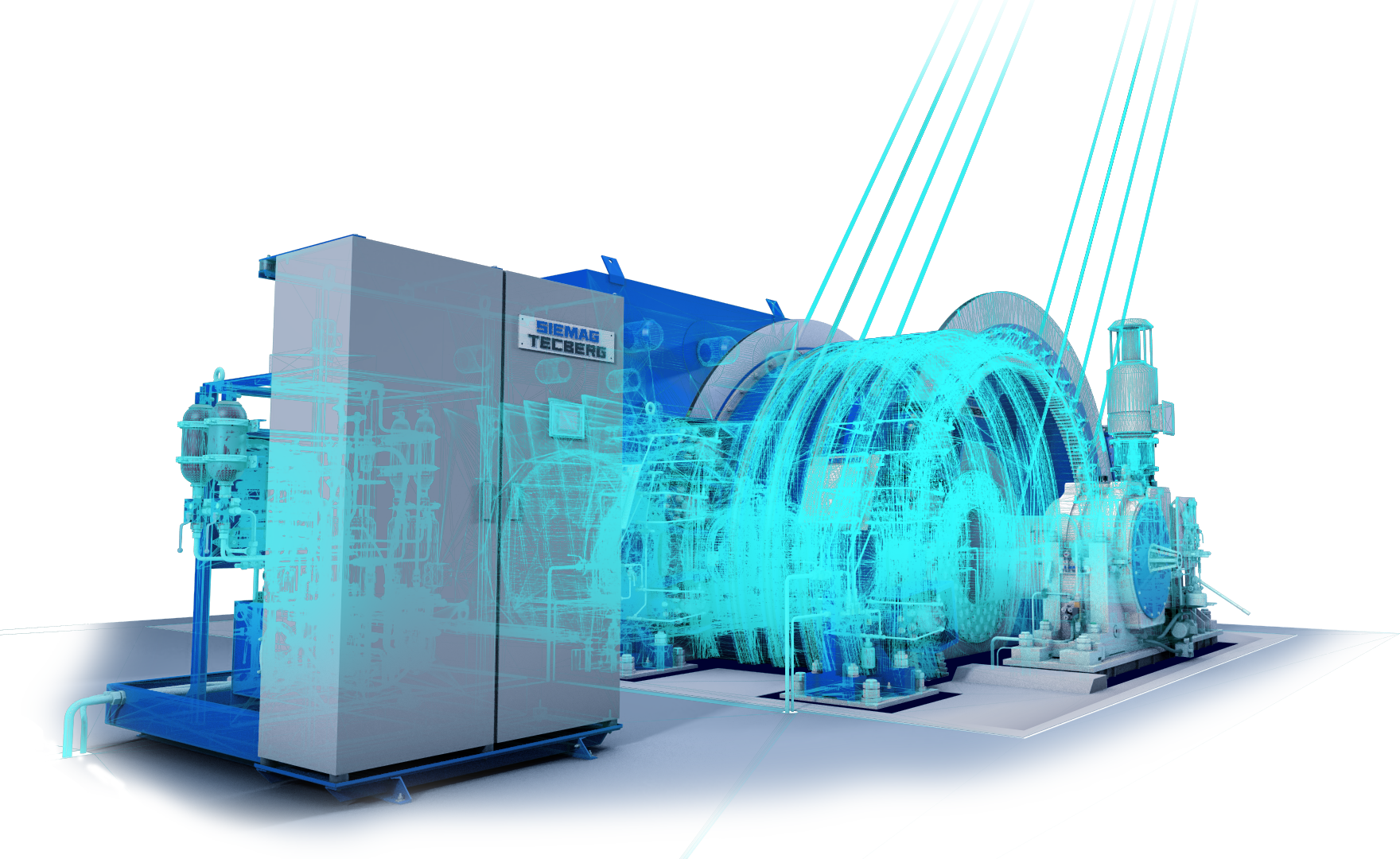

Condition Monitoring

Condition monitoring of hoisting machines to avoid downtime.

To avoid downtimes, information on wear reserves and early detection od damage to plant components are elementary! With "Condition Monitoring" from TECBERG digital, you have all the relevant data at your fingertips - always up-to-date, anytime and anywhere.

With the "Condition Monitoring" module, TECBERG digital provides you with a compact overview of the wear reserves and impending damage to plant components. In addition to the sensor data, selected process data is also processed on site or transmitted to the SIEMAG TECBERG Monitoring Center via a secure VPN connection and subjected to database-driven and self-learning trend analysis. If defined limit values are violated, an automatic alarm message is sent via e-mail or SMS to previously defined recipients in addition to the component-related desktop visualisation. In this way, maintenance work can be scheduled specifically for production-free periods and necessary resources can be scheduled early on.

The special: In addition to visualisation, alarm messages and reporting, TECBERG digital offers automatic feedback to your service management. The system triggers concrete maintenance proposals with recommendations for action, which can be conveniently and efficiently integrated into maintenance planning in the Service Management module.

Data security: Your data is transmitted via a secure VPN connection. The interfaces are protected by passwords and firewalls both on the system side and in the SIEMAG TECBERG Monitoring Center. Thus, your data is completely isolated from the public Internet, access is only permitted to authorized personnel and is strictly monitored.

Advantages for you

- Component-related trend analysis

- Alarm message via e-mail or SMS to specified recipients

- Transparency through online reporting

- Concrete recommendations for action

- Integrated service interface